High strength bolt is a new connection form developed in the 1950s. It has the advantages of simple construction, good mechanical performance, removable, fatigue resistance and no loosening under dynamic load. It is a promising connection method.

When assembling, the nut is tightened with a torsion wrench to produce a huge and controlled pre-tension Fp. Through the nut and lining plate, the pre-tension Fp of the same size is produced for the connecting parts. Under the action of pre-pressure Fp, there will be greater friction along the surface of the joints. Obviously, as long as the sliding force F is less than the friction force, the components will not slide and the joints will not be destroyed. This is the principle of high strength bolt connection.

As mentioned above, high-strength bolt connections are prevented from sliding by the friction between the contact surfaces of the connectors; in order to make the contact surfaces have enough friction, it is necessary to improve the clamping force of the components and increase the friction coefficient between the components. The clamping force between components is achieved by applying pre-tightening force to bolts, but the pre-tightening force of ordinary bolts made of low carbon steel is limited due to the limitation of material strength, and the friction force produced by them is smaller than the shear force of ordinary bolts. Therefore, if the force is transmitted by the friction force caused by pre-tension force of bolts, the bolts will be used. The strength of material must be much greater than that of component material. That is to say, bolts must be made of high strength steel, which is also the reason for high strength bolt connection.

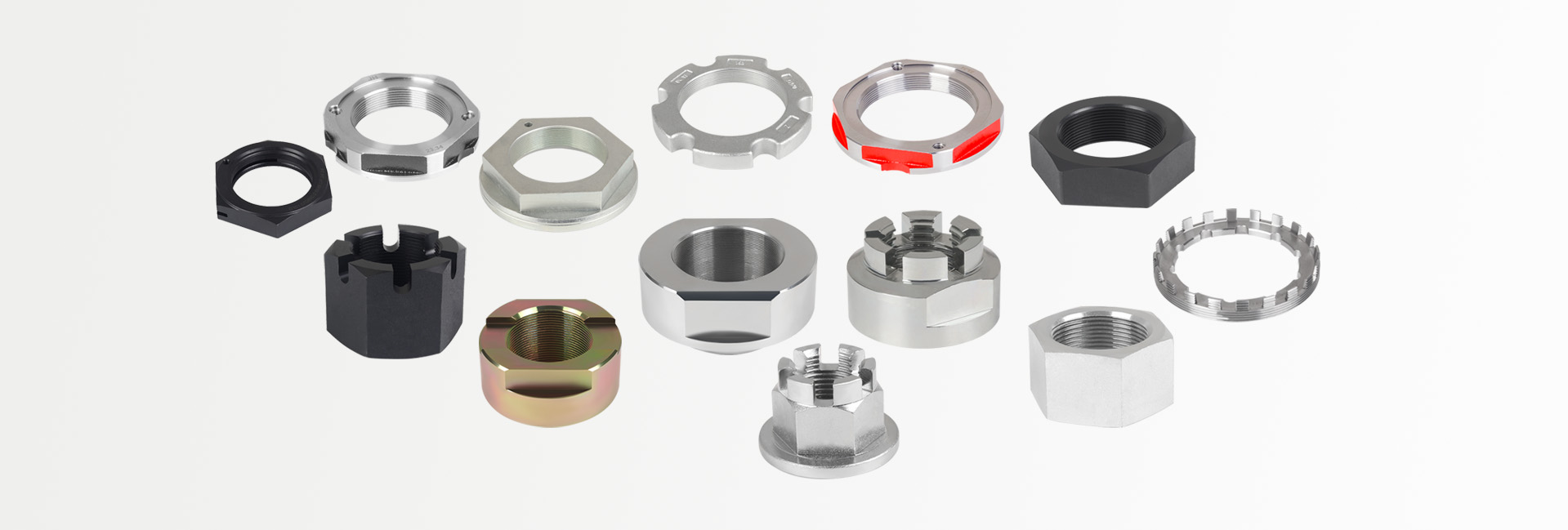

The strength of materials used for high strength bolts is 4 to 5 times that of ordinary bolts, and the commonly used performance grades are 8.8 and 10.9. Grade 8.8 adopts high quality carbon steel 35 or 45, and grade 10.9 adopts alloy structural steel 20MnTiB, 40B and 35VB. High strength bolts have two types: large hexagonal head bolts and Torsion-shear bolts. According to the steel structure code, the material of high strength bolts should conform to the current standard.

The pre-tension force of high strength bolts is determined by the yield of materials and the effective area of bolts, taking into account a certain friction coefficient. The pre-tension force of high strength bolts is established by fastening nuts during construction. There are several ways to fasten (tighten) nuts as follows:

(1) torque method

According to the relationship between the torque M and the pre-tension, the nuts are initially tightened with a common wrench, and then the special wrench which can display the value of the torque is used to tighten the nuts to the specified value of the torque.

(two) corner method

According to the close contact between the plates, the rotation angle of the nut is proportional to the pre-tension of the bolt.

When tightening, the nut is screwed to the non-rotating position with a short wrench, and then the nut is screwed to the specified position with a long wrench to achieve the pre-tension.

(3) Turn off the tail of the bolt

Used for torsion shear type high strength bolt, this bolt has a special tail. When tightening, the special wrench glove is used to hold the bolt and the bolt tail. One sleeve rotates forward and the other sleeve reverses. When the nut is tightened to a certain extent, the bolt tail is screwed off. Because the groove depth at the end of the bolt is determined by the relationship between the twisting torque and the pre-tension force, the corresponding pre-tension force is achieved when the bolt is twisted.

In high strength bolted connections, the magnitude of friction coefficient has a great influence on the bearing capacity. The test shows that the friction coefficient is directly related to the material quality of the component, the roughness of the contact surface and the magnitude of the reverse force. The main factors are the form of the contact surface and the material quality of the component. In order to increase the friction coefficient of the contact surface, the contact surface of components in the connecting area should be treated during construction, such as sandblasting and cleaning with wire brush. In the design, according to the engineering situation, the treatment method with larger friction coefficient should be adopted as far as possible and clearly indicated on the construction drawing.

In addition to the above treatment, there is also a method of grinding contact surface with portable electric grinding wheel. The direction of grinding should be perpendicular to the direction of force, and its anti-sliding coefficient is equivalent to that of sand blasting treatment.